Triodetic Advantages

Tailored Cladding for Precision

Our cladding systems are custom-designed to optimize project execution, reducing installation time and costs. By eliminating errors and on-site waste, we ensure precise and efficient integration, enhancing protection and structural performance.

Seamless Integration with Operational Mines

Designed to work within existing mining operations, our solutions ensure minimal disruption, allowing your projects to proceed smoothly without costly downtimes in mine domes and stockpile domes.

Built for Heavy Loads

Our structures are engineered to support additional heavy equipment like conveyors, ensuring your operation runs efficiently without compromising safety.

Long-lasting and Cost-effective

Triodetic structures are designed for longevity and seamless integration with other infrastructures, reducing operational expenses (OPEX) and extending the lifespan of your investments.

Faster, Simplified Construction

Pre-assembled components ensure faster on-site construction, reducing labour costs and streamlining the entire building process, making it ideal for prefabricated structures and dome construction.

Flexible and Resilient Foundations

Our systems are highly adaptable to various topographies and soil conditions, ensuring stability and durability in even the most challenging environments.

Simplified, Strong Design

Our single-layer structures require very little reinforcing, offering a streamlined yet robust solution that reduces material costs and simplifies the construction process.

Natural Light with Customization

Our systems, with customizable translucent panels, provide natural lighting options, improving energy efficiency and creating a more productive environment.

Summary of Projects

Our mining domes are specifically engineered to withstand harsh environmental conditions and heavy loads, making them an ideal choice for any mining project. Each mine dome we design is crafted with precision, ensuring it meets the exact specifications of your site and operations.

| Location | Name | Description | Application | Client |

|---|---|---|---|---|

| Argentina, Jujuy Province | Pirquitas Mine | 64 m diameter | Silver Mine | SSR Mining |

| Argentina, San Juan Province | Veladero Argentina (Dome Stockpile) | 57 m diameter | Gold Mine | Barrick / SNC LAVALIN |

| Arizona, US | Safford Mine (Dome Stockpile) | 125 m diameter | Copper Mine | FLUOR Canada/Freeport McMoran |

| Canada, British Columbia | Highland Valley Copper 1 (Dome Stockpile) | 105 m diameter | Copper Mine | TECK Copper, Highland Valley Copper |

| Canada, Nunavut, Tundra region, Sub Arctic | Meadow bank (Dome Stockpile) | 62 m diameter | Gold Mine | Agnico Eagle Ltd. |

| Canada, Ontario, Gogama | Cote Gold Mine (Dome Stockpile) | 83 m diameter | Gold Mine | IAMGOLD and Sumitomo Metal Mining Co |

| Canada, Ontario | Greenstone Mine (Dome Stockpile) | 81 m diameter | Gold Mine | GMining/Greenstone Gold Mine |

| Canada, Quebec | Val D’or (Dome Stockpile) | 62 m diameter | Gold Mine | Agnico Eagle Ltd. |

| Canada, Timmins, Ontario | Bell Creek – Lake Shore Gold (Dome) | 55 m diameter | Gold Mine | Lake Shore Gold Corporation |

| Canada, Vanscoy, Saskatchewan | Agrium (Dome) | 45 m diameter | Potash Mine | Agrium Inc./ SNC LAVALIN |

| Chile, Atacama Desert, close to mining town of Sierra Gorda | SPENCE Project (Dome 1) | 80 m x 60 m Dome | Copper Mine | BHP Billiton / FLUOR |

| Chile, Atacama Desert, close to mining town of Sierra Gorda | SPENCE Project (Dome 2) | 110 m diameter | Copper Mine | BHP Billiton / FLUOR |

| Chile, Comuna de Calama, Prov. El Loa, Antofagasta Region | Radomiro Tomic Phase II (Dome Stockpile) | 135 m diameter | Copper Mine | CODELCO / JACOBS |

| Chile, Desert de Atacama | Escondida Chile (Longitudinal Stockpile) | 156 m x 60 m | Copper Mine | BHP Billiton |

| Chile, IV Region de Coquimbo, Province of Elqui | Andacollo (Dome Stockpile) | 92 m diameter | Copper Mine | TECK, Mining Company Carmen de Andacollo |

| Kuwait, Al Zour | Twin Domes Al Zour Refinery | 87 m diameter (2) | Sulphur Storage | Fluor-Hyundai-Daewoo - (KNPC) |

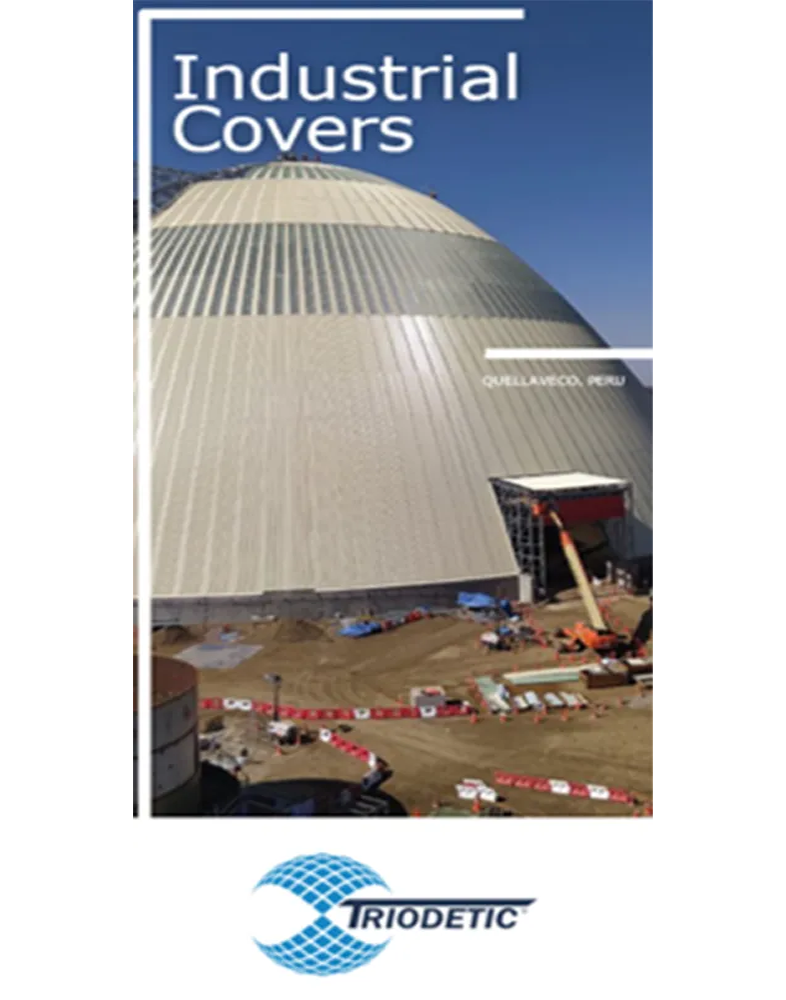

| Peru, Moquegua | Quellaveco mine (Dome for Stockpile) | 124 m diameter | Copper mine | Fluor Chile / Anglo American |

| Perú, Distrito Ilabaya, Department of Tacna | Toquepala Phase 1 (Dome Stockpile) | 115 m diameter | Copper Mine | Southern Peru Copper Corporation |

| Perú, Distrito Ilabaya, Department of Tacna | Toquepala Phase 2 (Dome Stockpile) | 75 m diameter | Copper Mine | Southern Peru Copper Corporation |

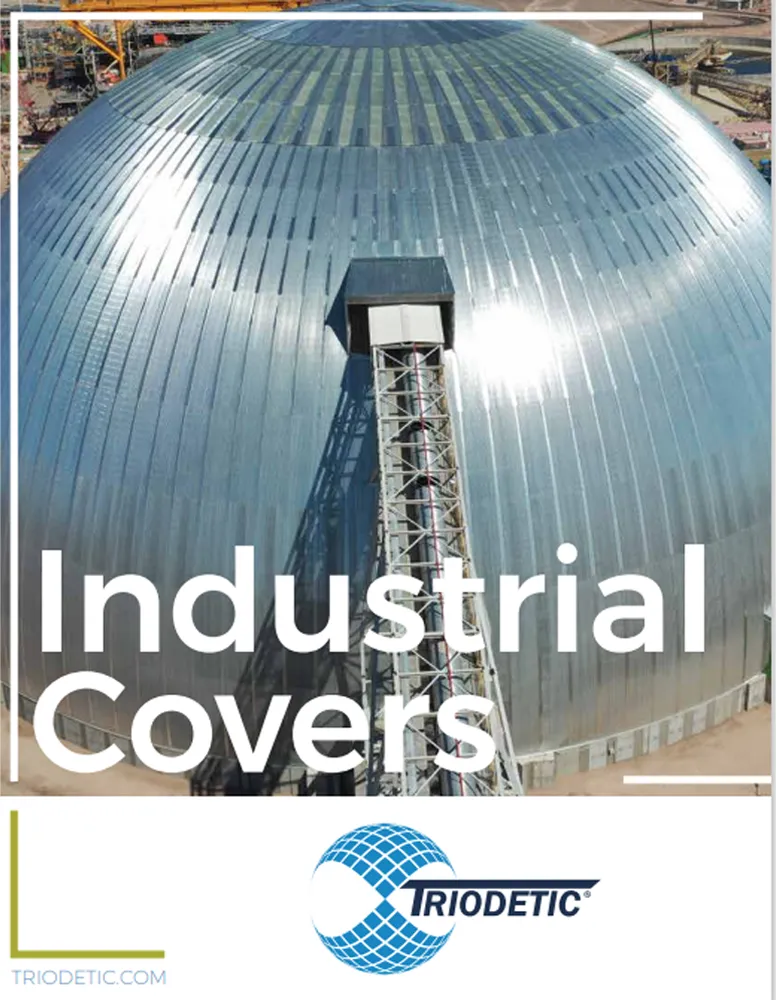

Brochures

Case Studies

Canada: Leading Producer of Minerals

Canada is a global leader in mineral production, contributing significantly to global consumption with advanced mining techniques and rich resource reserves. Mining in Canada began in Saskatchewan in the 1940s, with the discovery of high-grade mineral layers in the 1950s. These layers, formed millions of years ago by an evaporated inland sea, represent some of the world’s richest mineral reserves.

Mining and Corrosion Challenges

In Saskatchewan, minerals are mined using conventional methods. Large rotary machines cut tunnels into the ore body, leaving salt pillars as supports. The crushed ore undergoes a flotation process, creating a highly corrosive mixture that can damage piping, containment vessels, and machinery. Engineers and maintenance personnel continuously work to protect facilities from corrosion.

Corrosion Protection Strategies

Metal corrosion is a significant issue, causing material deterioration through chemical and electrochemical reactions. The process systems and ambient air can cause corrosion in facilities handling corrosive materials. Using stainless steel and specialized coatings can help resist this damage, though coatings can be compromised, leading to progressive corrosion and structural failures.

Case Study: Agrium Mine Expansion

The Agrium mine, now known as Nutrien, near Saskatoon, underwent an extensive expansion that called for a sophisticated and durable solution for covering a critical flotation tank. The project demanded a dome that could withstand the aggressive environment while providing robust support for the ongoing operations.

The resulting dome, with a diameter of 45 m (146 ft) and a height of 19 m (63 ft), is a testament to advanced engineering and material science. Made from stainless steel 316L, the structure includes several large dormers around its perimeter. These openings, measuring 4 m (14 ft) wide and 14 m (45 ft) high, accommodate a bridge truss frame that supports the central rotating mechanism and pipe conduits.

Despite the complexity added by these dormer openings, which interrupted the geometric pattern of the triangular elements, the structure’s integrity was maintained through special tubular reinforcements. This attention to detail ensured the dome’s stability and durability during and after assembly.

The dome is covered with pre-curved corrugated stainless steel decking, followed by a 90 mm (3.5 in.) layer of spray-on insulation topped with a UV-resistant membrane. This three-layer insulation system, consisting of Premicote 429 primer, Bayseal 3.0 closed-cell polyurethane, and Rhino Eco Coat exterior membrane, ensures that the facility remains protected against extreme winter temperatures, maintaining operational efficiency throughout the year.

Conclusion

As the global population grows, so does the demand for minerals. Mineral demand is expected to increase annually, driving investments in mining expansions and new operations. Designing long-lasting production systems is essential to minimizing corrosion and controlling maintenance costs. Utilizing stainless steel and durable coatings will enhance the longevity and efficiency of mining operations.

Media

Contact Us

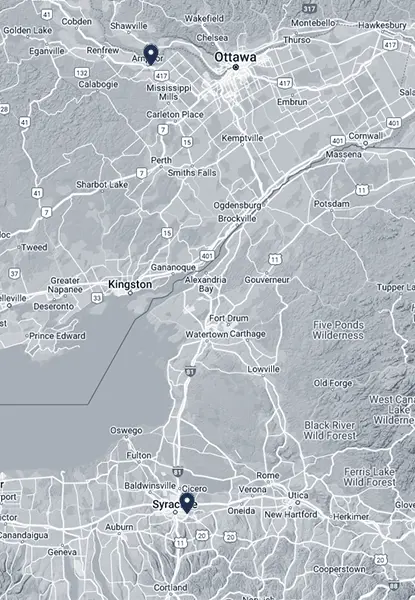

CANADA

10 Didak Road Arnprior, ON K7S 0C3

T: +1 (613) 623-3434

T: +1 (800) 565-2743

F: +1 (613) 622-4003

USA

4465 East Genesee Street PMB 306 Syracuse, NY 13214 – 2253

T: +1 (800) 565-2743

SOUTH AMERICA

Contact: Mijail Triana Fernandez

Project Lead Mining

T: +1 (800) 565-2743

AUSTRALIA

ALLSHELTER 19 John Street Lawson NSW 2783

T: +1 (800) 565-2743

Sales

Marc Brule

Sales Manager

Toll free: 1 800 565 2743 Ext. 2234

Cell 1+ 613 857 9872

Desk 1+613 623 3434 ext 2234

Email: mbrule@triodetic.com

News & Events

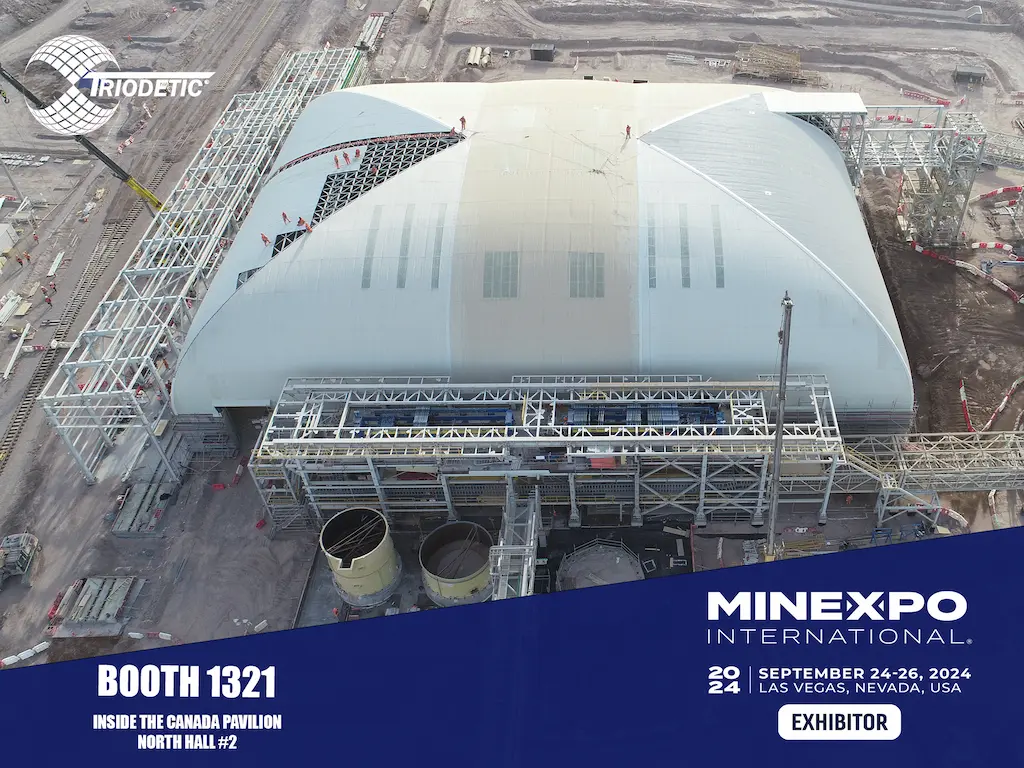

MINEXPO LAS VEGAS 2024

We're excited to announce that Triodetic will showcase our latest innovations at MINExpo 2024 from September 24 to 26! Get ready to witness the impact of our groundbreaking mining domes and structural solutions, inspiring a new era in the industry.

Québec Mines + Énergie 2024

Join Triodetic at Québec Mines + Énergie 2024 to explore how our custom-engineered domes transform the mining industry. Designed for rapid installation, durability, and adaptability to any terrain, our structures cut costs, enhance safety, and reduce environmental impact. Visit us at Kiosk 103 to see how we’re building a smarter, cleaner future for mining in Québec!

PDAC 2025 – Toronto, Canada

Triodetic will be at PDAC 2025, showcasing our structural engineering solutions with geodesic domes designed for the mining industry. Our structures ensure fast installation, high durability, and contribute to sustainable architecture, reducing environmental impact.

Perumin / Extemin 2025 – Arequipa, Peru

🔍 At PERUMIN we will showcase how Triodetic domes turn challenging terrains into opportunities. Installed directly on compacted embankments, they enable faster schedules, safer construction, and reliable performance under demanding mining conditions. With over 60 years of experience, Triodetic delivers resilient and sustainable solutions for the future of mining.

PDAC 2026 – Toronto, Canada

Triodetic structures support enclosed storage, dust mitigation, long-term performance in extreme climates, and efficient installation with minimal site disruption. Sustainable engineering is not an add-on. It is part of the structural logic from day one.

Network with our experienced team and discover what sets us apart. Triodetic industrial domes at MINExpo Las Vegas, highlighting mining domes and structural engineering solutions for the mining industry.

Please save the date and visit our booth (1321) for an unforgettable experience.

Join us at Booth 1321 to discover how our cutting-edge domes can elevate your mining operations. Whether you want to optimize your processes or innovate with new structural designs, our team is here to help you achieve your goals.

Join us at our booth, where our experts will give live demonstrations on how our innovative domes and structures effectively manage dust emissions, protect worker health, and ensure compliance with environmental standards. Learn the science and engineering behind our solutions and see how they can be applied to your needs.

Stop by our booth to experience firsthand how our team of specialists showcases the capabilities of our cutting-edge domes and structures. See how they efficiently control dust emissions, promote workforce safety, and maintain strict environmental compliance. Delve deeper into the underlying science and engineering that power our solutions, and explore how they can be adapted to meet your specific needs.

Visit us at booth #7028N from March 2-5 and discover how to optimize your mining operations with innovation and efficiency.

📍 Pavilion 5 · Canada Pavilion · Booth 677.

Join us at PDAC 2026 Booth #7028N

FAQs

What types of structures does Triodetic specialize in?

Triodetic specializes in engineered structures such as geodesic domes, space frames, and custom architectural solutions. These structures are used for industrial applications, waterparks, entertainment venues, and pedestrian bridges.

How long has Triodetic been in operation?

Triodetic has been in operation since 1962, providing over 60 years of expertise in the design and construction of engineered structures.

What are the benefits of using Triodetic's structures?

Triodetic’s structures are known for their durability, efficiency, and sustainability. They use recycled materials, consume less energy, and are designed to withstand harsh environmental conditions.

Can Triodetic retrofit existing structures?

Yes, Triodetic offers customization and retrofit services to enhance the structural integrity and functionality of existing buildings.

What industries does Triodetic serve?

Triodetic serves a variety of industries, including mining, environmental storage, waterparks, entertainment, and infrastructure projects.

Are Triodetic's structures environmentally friendly?

Yes, Triodetic is committed to sustainable building design. They use recycled materials, reduce material consumption, and employ non-polluting fabrication processes.

What is the largest dome span that Triodetic can construct?

Triodetic has designed and manufactured domes up to 145m in diameter. Our Structural engineers are excited to take on new challenges, meaning ”bigger.”

Just let our engineers make the impossible happen.

Where can I find examples of Triodetic's work?

Does Triodetic provide international services?

Yes, Triodetic operates internationally, with projects completed across North America, South America, Europe, Asia, and other regions. To discover more about the locations where Triodetic has left its mark, visit our interactive project map and explore the diverse range of projects we’ve completed around the globe.

What materials are used in Triodetic's structures?

Triodetic’s structures can be constructed using galvanized steel, painted steel, aluminum, or stainless steel, depending on the specific requirements of the project and environmental conditions.

What types of storage domes does Triodetic offer?

Triodetic specializes in a wide range of storage domes, each uniquely designed to meet the specific needs of various industries. Our custom-engineered solutions are adaptable and versatile, catering to a diverse range of applications.

- Grain Storage Domes are ideal for agricultural applications, providing safe and durable storage for large quantities of grain.

- Cement Storage Domes: Engineered to withstand the demanding conditions of cement storage, ensuring material integrity.

- Clinker Storage Domes: Built to handle the extreme heat and heavy loads of clinker storage.

- Limestone Storage Domes: These are designed for storing limestone, offering protection against the elements and maintaining material quality.

- Port Storage Domes: Perfect for port facilities, these domes are optimized for the storage of bulk materials and easy transport access.

- Coal Storage Domes: Providing secure and environmentally friendly storage for coal, reducing dust and minimizing environmental impact.

- Lithium Storage Domes: Tailored for the energy sector, these domes ensure the safe and efficient storage of lithium and other sensitive materials.

- Silver Storage Domes: These domes are designed to protect valuable silver reserves, and they have advanced features to prevent corrosion and material degradation.

While these are some of our most popular storage dome options, we are not limited to these solutions. Triodetic is committed to meeting your unique storage needs, offering a wide array of custom designs to ensure that your materials are stored in the most efficient and secure manner possible. If you have unique requirements, our team of experts can work with you to develop a custom-engineered structure that perfectly fits your project.

How do Triodetic's dust control domes help in managing environmental concerns?

Triodetic’s dust control domes are designed to minimize dust emissions and manage the environmental concerns associated with bulk material storage and handling. These domes provide an effective solution by fully enclosing materials such as coal, minerals, and other particulate matter, preventing dust from escaping into the surrounding environment.

Our dust control domes are engineered to meet regulatory standards and can be customized to suit various industrial applications, including mining, power generation, and port operations. By choosing Triodetic’s dust control domes, you ensure compliance with environmental regulations and contribute to a cleaner and safer working environment, reducing the risk of respiratory issues and other health concerns for workers and nearby communities.

What are Space Frames and how are they used in industrial projects?

Space Frames are three-dimensional structures made of interconnected bars that evenly distribute loads. They are ideal for creating lightweight yet strong roofs, façades, and covers. In industrial projects, they offer a combination of durability and efficiency, enabling functional and high-performance designs.

How do you define a dome, and what is the meaning of domes in mining, storage, and construction?

A dome is defined as a curved architectural structure that covers a space without the need for internal columns, providing an efficient and durable solution for various applications. Domes meaning in construction refers to their ability to offer durability, structural efficiency, and adaptability to different environments.

In mining, domes are used for mineral storage and environmental protection, reducing dust dispersion and improving working conditions. In the construction industry, domes enable more resilient and large-scale infrastructure, optimizing space use and enhancing structural efficiency.

Triodetic designs custom industrial domes that integrate innovation, sustainability, and durability to provide optimal solutions for mining, energy, and storage applications.