St. Jude’s Igloo Cathedral: Engineering Faith and Resilience in the Arctic

Rebuilding a Sacred Landmark in the Arctic

In Iqaluit, Nunavut, a church like no other rises from the Arctic landscape: St. Jude’s Igloo Cathedral. After the original cathedral was destroyed by arson in 2005, the new igloo-inspired church reopened on June 3, 2012, restoring a spiritual home and a symbol of resilience for the Iqalummiut community. Described as a spiritual beacon, it blends cultural identity with modern engineering in one of the world’s harshest climates.

Designing an Igloo for Modern Engineering

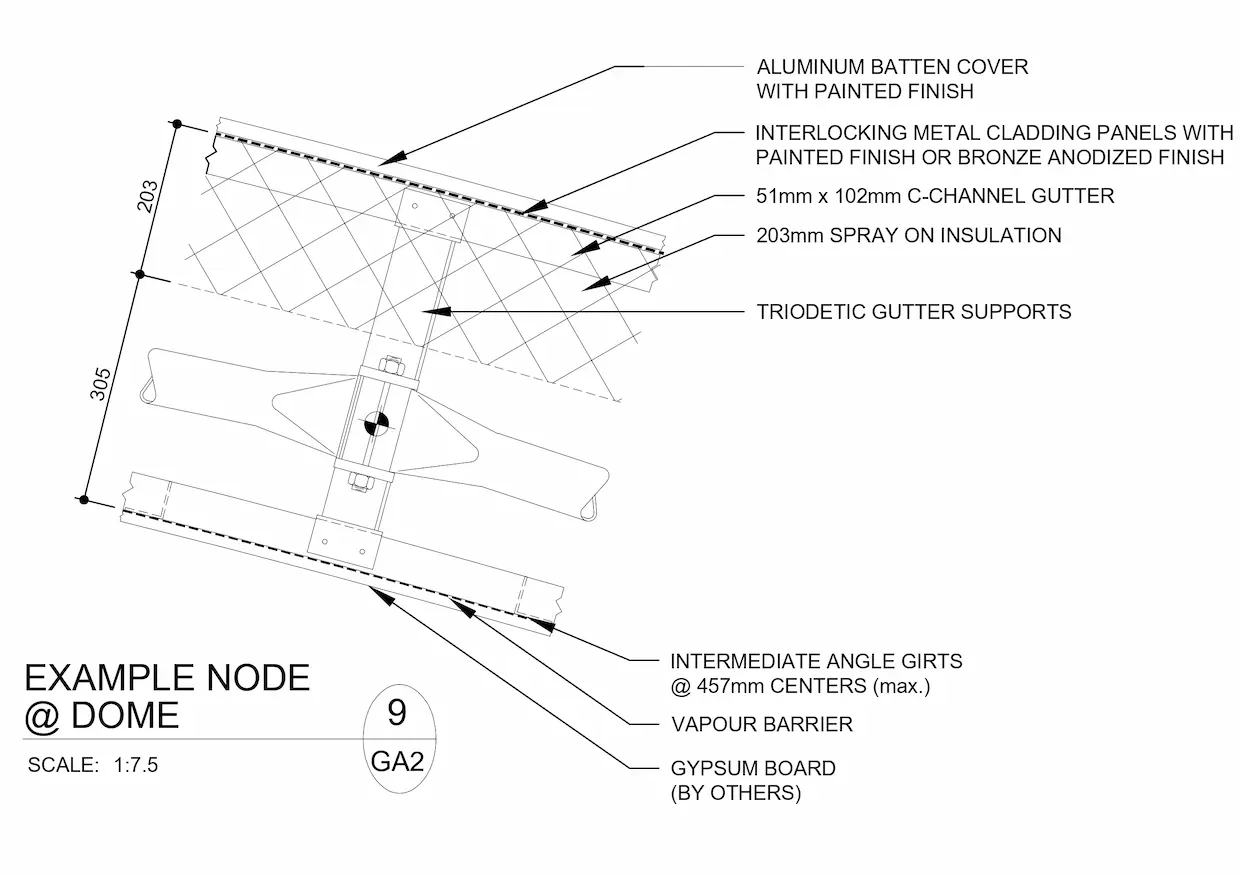

The building is organized around a 30-meter-diameter dome with a large barrel-vaulted entrance vestibule. The envelope covers 11,288 ft² and is subdivided into 40 modular sections that streamline fabrication and assembly while preserving the iconic igloo form. Custom gutters facilitate the transition between the dome and the barrel vault, ensuring a watertight envelope. At the apex, a 12.3 m spire topped with a cross includes a skylight that brings natural light into the sanctuary. The design and detailing conform to the National Building Code of Canada.

Materials Built for Extreme Climates

The structural frame is constructed from ASTM A500 Grade C Flowcoat galvanized steel tubes, specifically chosen for their strength and durability in Arctic wind, snow, and thermal conditions. The exterior cladding consists of 24-gauge pre-painted Agway steel panels, designed to withstand severe weather conditions.

Thermal performance is provided by spray foam insulation applied to the underside of the exterior panels, with interior framing that supports drywall to create a warm, efficient interior.

Assembly and Installation Timeline

The project followed a precise and efficient schedule: 50 days for design and detailing, 63 days for fabrication, and about 10 weeks for on-site installation. A six-person local crew, guided by experienced supervisors, assembled the dome using a small crane for 18 days and two scissor lifts for roughly two months. To control wind-induced motion at the apex, the cross arms were equipped with mass dampers that minimize resonance and vibration.

Technical Specifications Summary

- Geometry: single-shell dome, 30 m diameter, with integrated barrel-vault vestry.

- Surface area: 11,288 ft² across 40 modular divisions.

- Primary structure: ASTM A500 Grade C Flowcoat galvanized steel tubing.

- Exterior cladding: 24-gauge pre-painted Agway steel panels.

- Thermal envelope: spray foam insulation beneath exterior panels plus interior drywall framing.

- Apex assembly: 12.3 m spire with cross and skylight; cross arms equipped with mass dampers.

- Code compliance: designed and detailed to the National Building Code of Canada.

Construction Logistics in Arctic Conditions

Modularized components supported an efficient build in a severe climate, and custom gutters at the dome-to-vault interface were key to maintaining watertight performance. Local labor, working under experienced supervision and with appropriate access equipment, completed the assembly within the planned window.

A Community Landmark Reimagined

St. Jude’s Church is both a cultural landmark and a place of worship, uniting Inuit heritage with contemporary structural practice. Reborn as the Igloo Cathedral, it stands as a resilient, light-filled space for gathering and faith, reaffirming its role in the life of Iqaluit and its people.

Project Image Gallery

Contributors:

Executive Contributor

References and Further Reading:

-

Anglican Journal – New St. Jude’s Spire Set to Inspire

Overview of the reconstruction process and design of the new spire, highlighting its symbolic and structural importance within the community. -

CBC News – Iqaluit’s Igloo Cathedral Being Rebuilt

News coverage documenting the rebuilding efforts and the challenges of construction under Arctic conditions. -

Matterport Virtual Tour – Explore St. Jude’s Cathedral in 3D

An immersive 3D walkthrough of the cathedral, showing the interior dome geometry, skylight design, and architectural details. -

Wikipedia – St. Jude’s Cathedral (Iqaluit)

General background on the cathedral’s history, reconstruction timeline, and cultural significance within Nunavut.