Quellaveco Mine Dome Case Study: Engineering a 124m Structure.

An Engineering Marvel in the Peruvian Andes

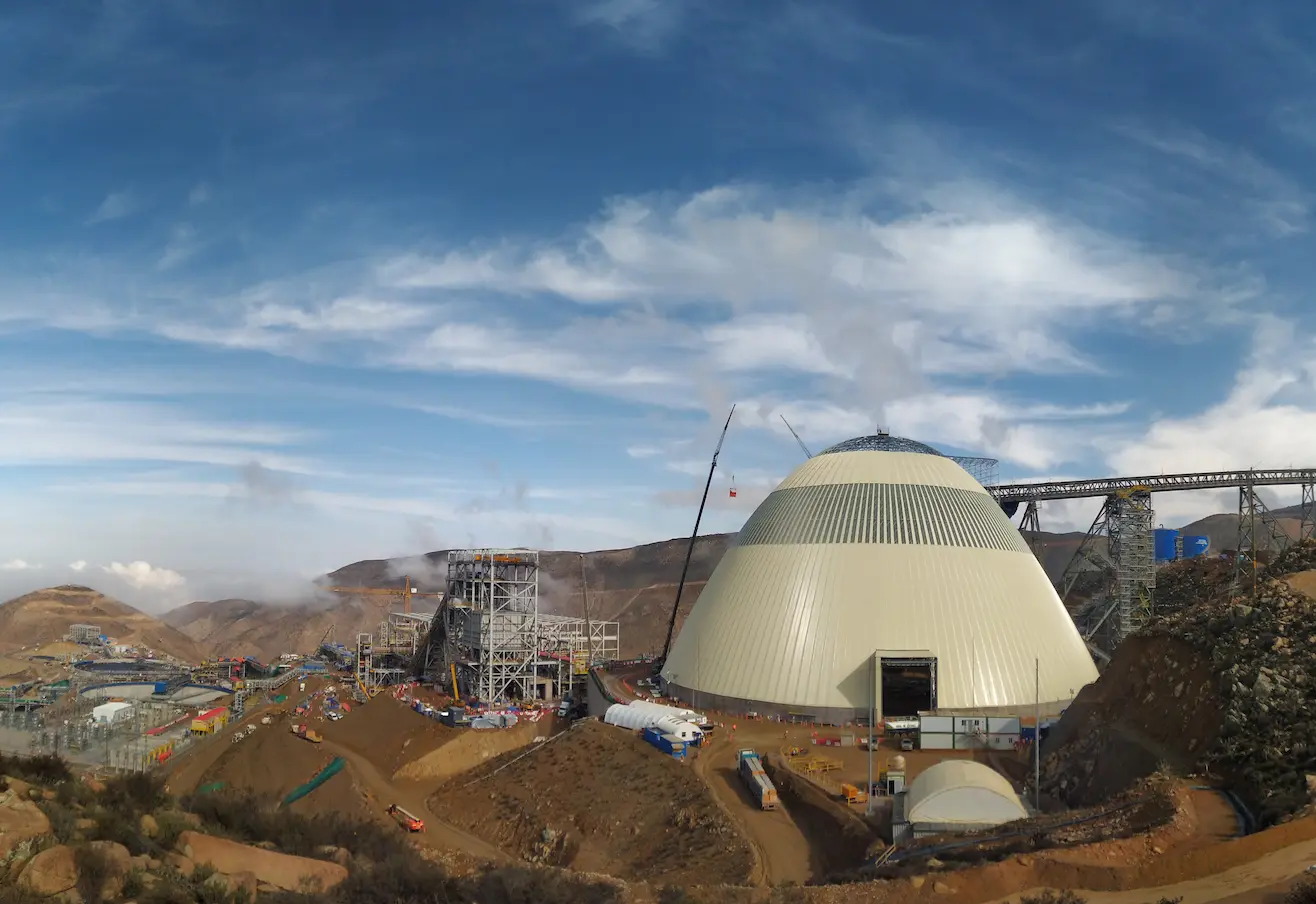

Rising high in the southern Andes of Peru, at the heart of the Quellaveco mine, stands a masterpiece that blends elegance with industrial power: the Quellaveco Dome. Completed in November 2022, this impressive parabolic structure not only shelters mining operations but also symbolizes technical mastery and international collaboration.

The Journey to Construction

Designing and building the dome was a feat of precision and perseverance. The process combined advanced engineering design and precision fabrication over a total of 34 weeks, carried out at Triodetic’s plant in Ontario, Canada.

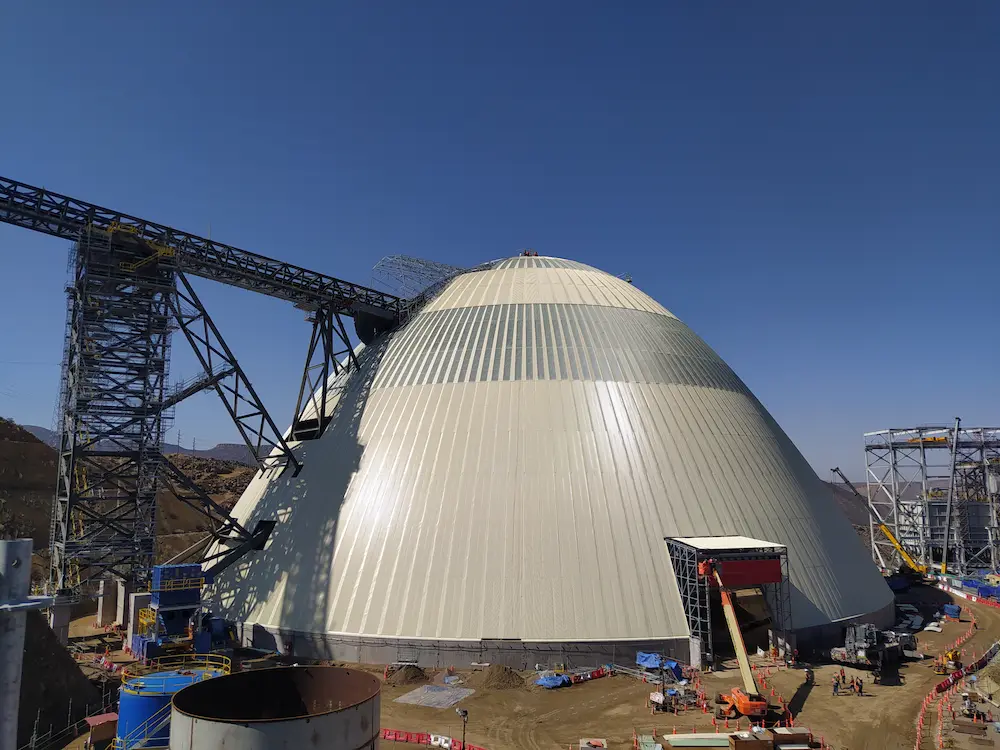

The dome spans 124 meters in diameter and reaches a height of 63 meters, supported by a 3-meter-high concrete wall that provides structural stability while adapting to the site’s uneven terrain.

Its double-curved parabolic geometry was chosen to:

-

Maximize strength

-

Minimize surface area

-

Withstand extreme environmental conditions

Engineered to Withstand the Elements

The Quellaveco Dome was designed to perform under some of the harshest environmental conditions. Located in Seismic Zone 3 and built on Soil Type SD (as classified by the International Building Code, indicating stiff soil conditions), it was engineered to withstand:

• Winds up to 100 km/h

• Snow loads of 40 kgf/m² (approximately 392 N/m²)

• Dust accumulation of 100 kgf/m² (approximately 980 N/m²)

Despite these challenges, the structure maintains full operational integrity while supporting large-scale industrial activity, including a conveyor system and heavy vehicle access.

Mastery of Materials and Structural Precision

To meet the site’s demands, the dome was built using ASTM A500 Grade C steel tubing, featuring:

- Wall thickness of 3.76 mm

- Diameters ranging from 65 mm to 135.64 mm

- Full galvanization using Flowcoat technology for maximum corrosion protection

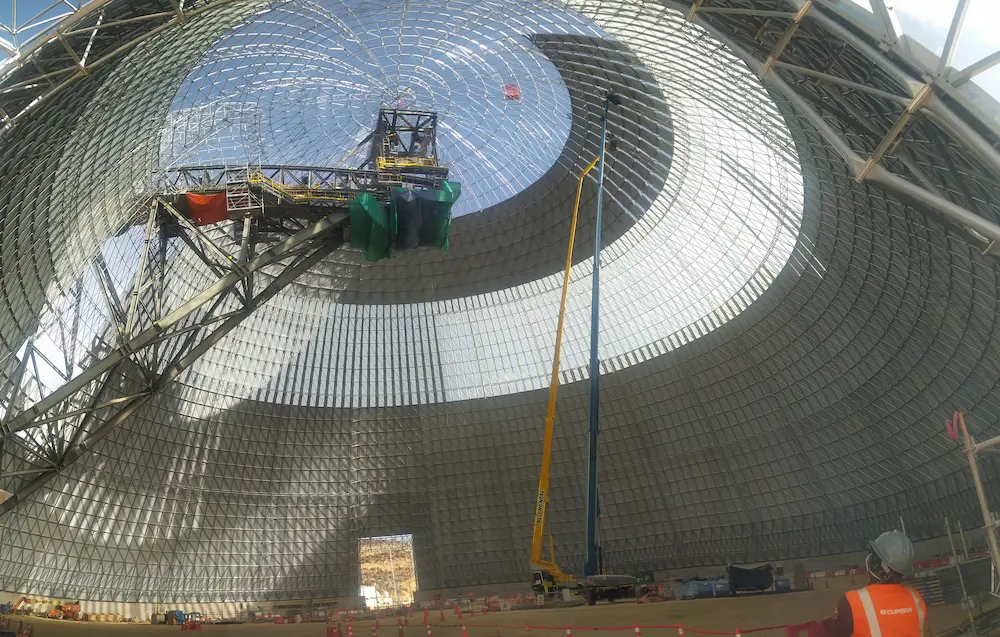

Approximately 20% of the surface is covered with translucent FRP (fiberglass-reinforced plastic) panels, allowing consistent natural daylight inside. To ensure functionality under any weather or visibility conditions, the dome includes over 80 strategically positioned luminaires, each weighing 50 kgf.

The outer cladding consists of 0.6 mm-thick (24-gauge) corrugated steel panels, painted on both sides with the Perspectra Plus coating system, providing long-lasting protection and aesthetic finish even in abrasive mining environments.

Complex Fabrication, Precise Assembly

Fabrication was a highly coordinated effort involving:

-

35 sets of technical drawings

-

5,868 fabrication hours

-

~45,840 components, including:

-

20,734 precision-formed tubes

-

5,194 hat channels

-

7,062 perforated and threaded connectors

-

Among other specialized components.

-

Each component was manufactured with tight tolerances and shipped to Peru, where the dome was assembled on-site with precision and efficiency.

Operational Integration

Functionality was central to the design. The dome includes:

-

Airtight sealing: Custom joint for a 4.5 x 3 m conveyor belt opening

-

Large-scale access: Two 10 x 10 m vehicular entrances for large equipment

Conveyor supports pass through the envelope and are carefully sealed using custom flashing and enclosures, permanently eliminating dust emissions.

“The dome doesn’t just protect the mineral; it optimizes our entire logistics chain. We now operate through winds that used to bring production to a halt.”

– Quellaveco Operations Manager

Seamless International Collaboration

Although designed and manufactured in Canada, the success of the Quellaveco Dome in Peru relied on more than engineering alone. All technical documentation was translated into Spanish by a bilingual team, enabling seamless communication with local partners. This cultural and linguistic integration was essential to the project’s execution and became a model of international engineering cooperation.

A Legacy for the Future

The Quellaveco Dome is far more than an industrial cover:

It is a testament to what’s possible when precision engineering, advanced materials, and global teamwork come together.

Built to serve the mining industry for decades while protecting nearby communities from dust emissions, it represents:

-

Durability

-

Efficiency

-

International collaboration

-

Engineering excellence in one of the world’s most demanding environments

This dome deserves to be recognized as the Machu Picchu of modern engineering.

Official Awards and Recognitions

-

Mining Technology Innovation (2025)

-

Perú Mining Excellence Awards – Congreso Internacional “Mining Peru and Latin America 2025”

-

For the use of automation, AI, robotics, and digitalization to enhance processes, safeguard people, and mitigate environmental impact.

-

-

National Mining Award – PERUMIN 36 (2023)

-

Instituto de Ingenieros de Minas del Perú (IIMP)

-

First place in Environmental Management / Biodiversity: Bio 4.0 – Intelligent and sustainable flora management at Quellaveco.

-

-

ProActivo Mining Award (2022)

-

ProActivo Magazine

-

Other Notable Achievements

-

Technology Innovation Excellence – Mining Technology Excellence Awards (2025)

-

Recognized at the Mining Technology Excellence Awards, an internationally respected program that celebrates innovation and sustainability in mining.

-

Contributors:

Executive Contributor